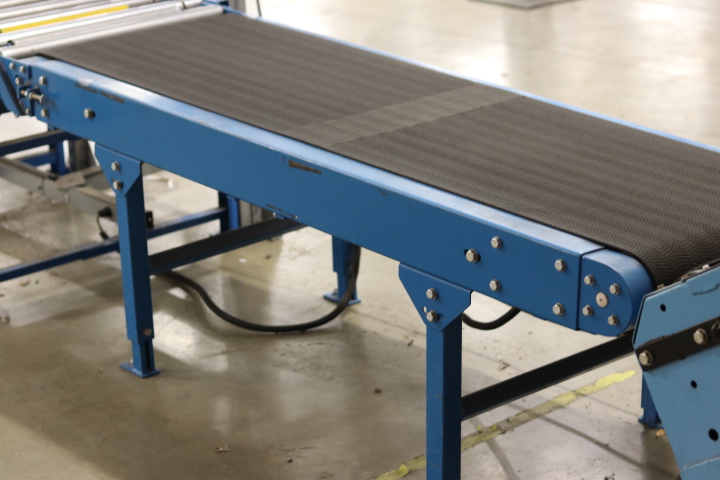

Belt Conveyors

Belt conveyors are widely used to carry load of bulk material along horizontal or inclined paths. They also carry light weight material from one spot of operation to another. They can be called the most commonly used conveying equipments. We manufacture various types of belt conveyors such as stationary portable and mobile conveyors that are capable of carrying high load to high extent of inclinations.

The belt conveyor that we offer is equipped with AEC 100 Friction Driven Belt Bends which ensures positive transfer of various products from various packages to bins. It has the capacity to carry load up to 50kg at speed that ranges from 5m/min to 60m/min without changing the position of the product.

Belt Conveyors – Conveying equipments

Listed below are some of its specific features :

• Sturdy solid framework

• Standard range of modules (can be customized on the clients request)

• High density conical end rollers

• 2Ply Non mono belting

• Vulcanized belt joints

• Positive belt guiding system

• Produce Low noise

• Facilitates Belt change within 30 minutes

PVC belt Conveyors

PVC (Poly Vinyl Chloride) Conveyor Belts, with single or multi plies, have a high application in various light, medium and heavy industries, including electronics, Food & Pharma, Bakery & Confectionary, Meat & Poultry, Packaging, Wood working, Glass, Ply & Board, Automobile, Health & Fitness, just to name a few.

We are Dynamic Industrials have the requisite expertise and experience to offer our clients superior range of imported conveyor belts such as PVC conveyor belts. We have facility of vulcanized joints, fused sidewalls and cleats, Tracking profiles to serve for elevating conveyors for food or other products. Made from premium grade of PVC material & fabric carcass, our PVC conveyor belts are happily being implemented and installed throughout various industries in India & other parts of the world.

Trough Belt Conveyors

Trough Belt Conveyors are designed to leverage the open frame and trough effect of the Rubber Belt Conveyors to fully contain the load of materials. Trough belt conveyors are the most widely used and efficient means of moving bulk materials Trough conveyors for light to medium capacity systems

These conveyors are used in areas of cement, coal packing, food industry, sand & gravel and package handling.

Truck Loading Conveyor

We are an acclaimed name in the market, engaged in presenting a superior quality array of Truck Loading Conveyor. The offered loader conveyors deliver high tensioning force up to 10T. Our professionals manufactured the loader conveyors using optimum grade materials along with adhering to industry standards. In addition, our professionals opt for strict quality inspection. Apart from this, clients can buy the loader conveyors from us at cost effective rates.

Features:

- High performance

- User friendly handling

- Flawless deliveries

Specifications:

- part one belt conveyor

- part two: section flexible motorized extension

- Specifications: effective width 600mm

- Total length: 4800mm for the belt part

- 1700-4200mm extendable for the motorized extension

- Height 700-2500mm adjustable

- Loading Capacity: 40kg/meter

- Speed : 10-20m/min

- Motor Power : 60w x 4, 1.5kw, 2.2kw, 380V/ 220V

- Main Material : MS, PVC belt, MS rollers

Flat Belt Conveyors,

We are offering Flat Belt Conveyors that are perfect to use for light- and medium weight loads between operations, levels and buildings. These are considered to be very useful when the conveyor path has an incline or decline. Flat Belt Conveyor are supplied for handling bags ie cement, sugar, chemical, cartoon etc with plain or rough top belt depending upon the requirement.

We had also supplied Side wall type Belt conveyor with steep inclination for handling chemical, sulphur, minerals, these are used where spaced is the limitation with low maintenance & operation cost.

Roller Conveyors

We make a wide range of Roller Conveyors classified as – Powered and non powered version conveyors using standard Precision bearings for heavy loads (250 kgs and above) and pressed bearings for lighter loads.

Many combinations offered in terms of Roller Pitch, Roller Diameter, Roller Moc, between frame width. Rollers are spring loaded with Hex axle or round axle. Please ask for our detailed catalogue

Powerised Roller Conveyor

We are engaged in offering Powerised Roller Conveyor that assures high performance and durability. The components of these conveyors are designed to deliver heavy duty usage as well as flexibility. They comprise broad walled rollers of sprocket, chain to chain or tangential chain mechanism, a fully enclosed side frame and an external shaft mounted motor. These powered roller conveyor comprises of component that are designed for both heavy duty usage and flexibility.

Features

Different materials of construction based on the application and usage Like in MS / SS 304 / PVC / PP/ SS 316L acid resistant

Applications / Solutions for

Assembly Lines

Packaging Lines

Warehouse conveying etc..

Add-ons to the Roller Conveyors:

Diverters, Convergers Lifters – Pneumatic, Mechanical

Traffic cop Mechanical / Automatic

Ball bed, Counters etc..

Gravity Roller Conveyor

A gravity conveyor moves the load without utilizing motor power sources, usually down an incline or through a person pushing the load along a flat conveyor. Gravity roller conveyors transport products or work in process from one work area to another. Titan gravity conveyors are a low cost and an ergonomic way to move materials.

There are 5 different models to choose from, ranging in capacities from 95 pounds to 3,000 pounds per roller. Titan offers numerous accessories such as curves, spurs, pop up stops, supports, ceiling hanger brackets, side rails, and optional rollers such as galvanized, stainless steel or plastic coated. Titan gravity roller conveyor is a valuable tool when designing a material handling solution for your application.

Chain Conveyors

In case of extremely heavy objects instead of the belts, there are conveyor chains that connect the object to its rear end. Apart from this, the conveyor chain is also one of the fixtures on the conveyor system that is used in the mechanical functioning of the system. Like the conveyor rollers, the chain plays a major role in the mechanical functioning of the conveyor belt.

Usually the conveyor control is directly linked or attached to the chain, and it is the speed of the chain that will determine how fast the entire process will finish. The conveyor chain is generally fabricated from metal. It is available in various qualities, shapes and sizes to suit various needs and requirements. In case the conveyor chain gets damaged at any given point, then it can be replaced. Ideally, the conveyor chain should be changed or serviced on a periodic basis, because any damage to the chain slows down the functioning of the conveyor.

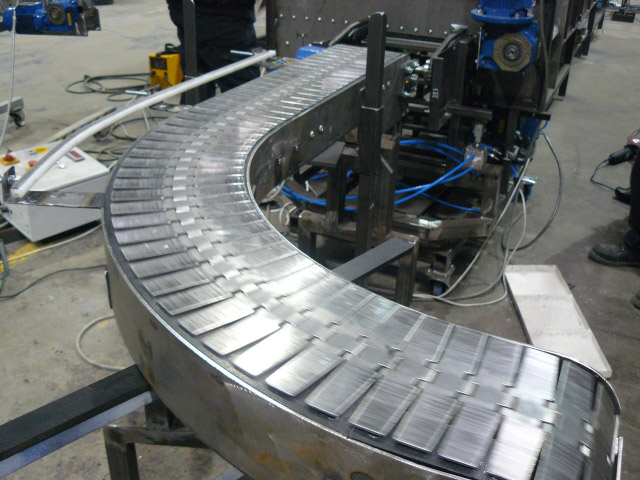

Slat Chain conveyors

Slat Conveyors are built with wood or metal slats attached to a single or double strand chain. In addition to carrying out operations, they may be used as a traveling platform, or a combination of the two. Many kinds of parts and packages can be carried light, heavy or bulky units on inclines as well as on the horizontal. Slats can be designed and shaped to suit the articles to be handled or the industry that it caters to.

Slat Conveyors can be applied easily to bring about a steady, orderly flow of material through a working unit or plant, eliminating confusion, promoting efficiency and effecting important savings in the expected cost.

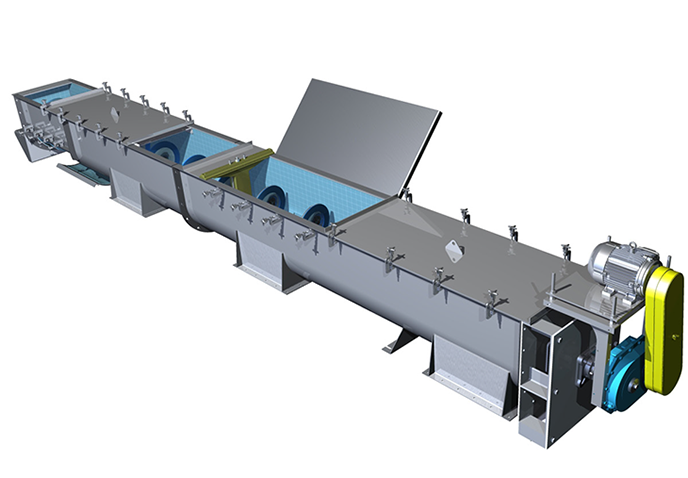

Drag Chain Conveyors

A Drag Chain Conveyors is a conveyor in which the open links of a chain drag material along the bottom of a hard-faced MS or SS trough.

The flights are fixed between two strands of chain, drags the material from feeding end to the discharge end in open or closed trough. These are available in different widths and lengths as per the site requirements and are also used for handling slightly sluggish, loose or lumpy hot material.

Drag Chain Conveyors are designed for horizontal, inclined and vertical transport of sawdust, chips and other bulk goods.

Feature of our conveyors is dust-proof, low noise and sealed design. We provide customized solutions to our clients as per the site situations.

Wooden Conveyor,

A conveyor belt that constantly halts or experiences problems is detrimental to productivity and increases overheads. In the wood industry, it’s essential that conveyor belts run at a reliable pace and deliver their load efficiently and safely.

Our wood conveyor belts are built to last and to operate at optimum performance. In a fast-paced processing environment, these characteristics are essential to ensuring wood is processed in the quickest time possible without any compromises on quality standards.

Sampla Belting conveyor belts are the versatile solution for an industry that requires a higher quality mode of product transportation. Our belts are suited to a wide range of wood applications including wood sanding machines, the conveying of large and partly finished panel products and also the transport of small product waste such as wood chips and sawdust.

Screw Conveyors

screw conveyors are the most widely used type of screw conveyor. Used to convey bulk materials from one part of a process to another, horizontal screw conveyors are available in a wide range of sizes, lengths, configurations and materials of construction.

Screw conveyors are typically designed to convey bulk materials at 15, 30 or 45-percent trough loading, depending upon material characteristics of the specific bulk material. As a general rule, trough loading of 45-percent can be used for light, free-flowing and non-abrasive bulk materials. Trough loadings of 15 and 30-percent are typically used for denser, sluggish and more abrasive bulk materials.

The inlet of a screw conveyor is always control fed by another device such as:

- Screw Conveyor

- Screw Feeder

- Belt Conveyor

- Rotary Airlock

- Volumetric or Gravimetric Feeder

The recommended location for the drive unit is on the discharge end of a screw conveyor which pulls the bulk material to the drive end. With this arrangement, each screw section is put in tension as the bulk material is conveyed toward the discharge of a screw conveyor, reducing wear and fatigue on the conveyor components.

Advantages of Using Screw Conveyors

- Ideal for conveying dry to semi-fluid bulk materials – free flowing to sluggish

- Cost-effective when compared to other conveying devices such as belt, pneumatic or aeromechanical

- Efficiently distributes bulk materials to various locations using multiple inlet and discharge points

- Totally enclosed for dusty, corrosive or hazardous environments