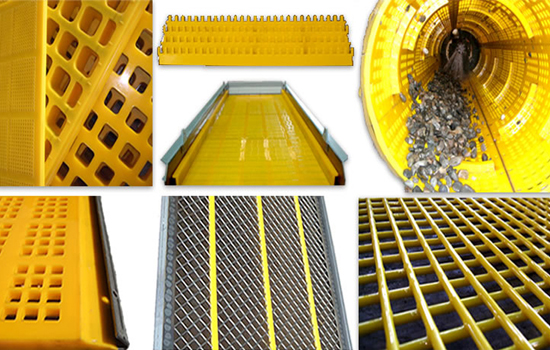

De Watering Screens

svsequipments manufactures dewatering screens for long-lasting performance in iron ore, coal, heavy minerals, base metals, mineral sands and diamond dewatering applications.

svsequipments extensive knowledge of the dewatering process has enabled it to create a range of dewatering screens that ensure an accurate removal of water without losing a high percentage of mineral fines with its precision-engineered aperture sizes from as small as 0.5 mm!

In order to ensure high performance and improve wear life in extreme vibrating screens, svsequipments has also developed the Saddle Top™ frame to provide the essential internal support for your dewatering screens on vigorous vibrating screens.

At svsequipments, your dewatering screens come standard with application knowledge, industry understanding, refined engineering and field service maintenance.

Features of our dewatering screens:

- Designed for high-frequency, low amplitude applications

- Minimise pegging and blinding with optimised designs

- Manufactured with secure screen fastening systems

- Designed for improved wear life in tough operating conditions

- Dewatering screens available in a wide range of apertures and panel thicknesses to suit any mineral application

- Reduced running costs as only worn dewatering screen panels need to be replaced

- Quick and simple installation and removal

De Watering Panels

Screenex dewatering screen panels are designed with high open area to achieve the highest reduction in moisture possible.

Having the reputation of manufacturing world class dewatering panel, we proffer a whole host of screen panel’s designs for dewatering applications as per the requirements set by our esteemed clientele. We have a committed and self-motivated team of professionals designing, developing and delivering customized dewatering panel; specific to our client’s needs.

At svsequipments, we persistently endeavor to hunt for ways so as to perk up our range of dewatering panel, to advance efficiency, wear life and to accommodate our customer’s requisites. Our dewatering screen panels are premeditated with high open area to attain the uppermost diminution in moisture achievable. We offer a wide range of reliable and exclusive dewatering panel that give optimize unsurpassed results.

Polyurethane Mats

Polyurethane Mat, Polyurethane Surface and Rubber under. With double sided non-slip surfaces, Sheep Mats exercise yoga mat comes with an excellent slip resistant advantage to prevent injuries. with ultra cushion and thickness (4mm), easy on your knees and elbows while you practice yoga, pilates or other mat exercises.

Features

- Bold, stimulating colors to energize your practice! Each mat has two colors and can be used on both sides.

- Thick, Durable & Lightweight,

- Hypoallergenic: No Latex, or harsh chemicals used in production

- Durable Closed Cell material means an ultra Hygienic mat that won’t absorb sweat.

Bonus Carrying

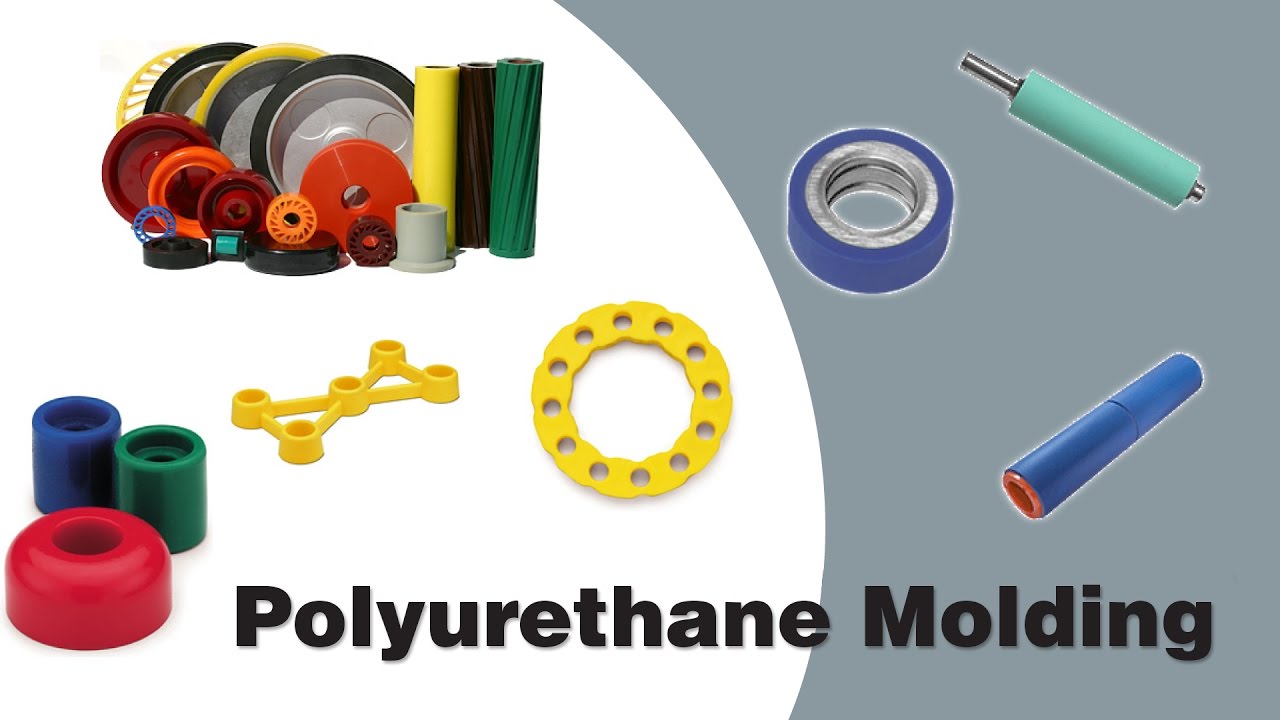

Polyurethane Screen

There are many benefits involved in using a polyurethane modular screening system which include the following:

- Easy changeover to maximise wear life and provide a more economical solution.

- High density precision injection moulded Polyurethane screening module.

- Modules available in: flat, inclined, with deflectors or weirs.

- Can be staggered on sub frame or supports for better screening.

- Support system used is firmly connected to screen frame.

- Specifically designed for all mining and quarry industries.

POLYURETHANE products,

We are an emerged manufacturer and supplier of Polyurethane PU Products based in India. We manufacture these Polyurethane PU Products using the top notch quality materials procured from the trusted vendors of the industry. We are capable of offering our clients with an impeccable range of Polyurethane PU Products that are known for their durability and extensive applicability in diverse applications.

These Polyurethane PU Products possess outstanding engineering properties for industrial applications. The inherent strength and ingrained superiority of the Polyurethane PU Products makes them most appropriate for different mechanical, chemical, thermal and electrical applications.

Our extensive range of Polyurethane PU Products has high coefficient of friction and good electrical and thermal properties that leads to its additional attributes to its applications. It has optimum resistance to chemical solvents and has a wide range of working temperature that makes it to be aggressively used in chemical and thermal industries.

These Polyurethane PU Products are also used in versatile engineering applications owing to their properties of excellent abrasion resistance coupled with high impact and tensile strength and tough tear strength. We can offer customized Polyurethane PU Products to exhibit low or high resilience or varying hardness respectively based on its varying applications.

Salient Features of Polyurethane PU Products:

- Excellent Abrasion Resistance

- Wide Resilience

- Noise & Vibration Damping

- Excellent Hydrolysis Stability

- Tough Tear Strength

- High Load Bearing Capacity

- Wide Hardness Range